“Quality doesn’t just happen. It is always the result of smart choices.” – Pio Tosini

For over 110 years, the Tosini family has cured legs of prosciutto in the small town of Langhirano in Emilia Romagna, Italy. It all began with Pio’s father, Ferrante Tosini, who slaughtered pigs and cured the meat in the back room of the family’s grocery store. After World War I, Ferrante and a young Pio began experimenting with new processing techniques and curing methods, gradually improving the business.

Today, Pio Tosini remains a family-owned and operated company, the torch of century-old traditions and passion is carried by Pio’s grandsons Nicola and Giovanni. (Meet Giovanni)

And in 2012–over 100 years since its inception–Slow Food Italy ranked Pio Tosini Prosciutto among the top 10 best Prosciutto di Parma.

What goes into making one of the best? Both a lot and yet very little.

The process is sort of complicated in it simplicity.

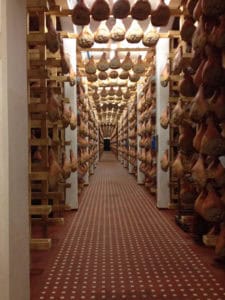

Let’s start with the simple part: there are really only the two ingredients of pork meat and sea salt. Pio Tosini actually uses less salt in their curing process than many prosciutto producers which means, in order to achieve sweetness, the ham must cure for a longer period– 20 months, to be exact. This is almost seven months longer than most other Proscuitto. Okay, so I guess that marks a third key component of the prosciutto’s quality: time. And of course the fourth critical element to the curing process is the dry sea breezes rolling across the hills, the chestnut and pine forests of Langhirano and through the open windows of the Pio Tosini curing house–almost divine in its awesome expansiveness.

Pigs, sea salt, time, natural air: And there you have it–a delicate ham with even salt penetration, nutty-sweet flavor and buttery texture. This nuanced flavor is due in great part by adding the milky whey from Parmesan cheese production to the pigs’ diet. Yes, it is a symbiotic merging of Parma’s two greats!

So, yes, on one hand keeping it simple is what makes it so exceptional.

But sometimes the most simple things require the most dedication to tradition and quality and the most patience and integrity–the most time.

Everyday during the curing process at Pio Tosini, Marinella–who has worked there for 30 years–tests each leg for abnormalities by inserting a horse bone into five different locations. The bone, called ago di osso di cavallo, is a great at absorbing and releasing odors very quickly. Marinella can tell, with her nose, if there is any spoilage in the meat, as well as making sure the ham is aged sufficiently.

Now that’s dedication! And the result is an extraordinary Prosciutto di Parma.

Now that’s dedication! And the result is an extraordinary Prosciutto di Parma.

But don’t just take our word for it. The high quality and traditional methods of Pio Tosini Prosciutto is ensured by the Consorzio di Parma brand which was set up in 1963 with “the objectives of safeguarding the genuine product, its tradition and the image represented by the designation ‘Parma.’”

And all of the deboning is done in house, a process that many other Prosciutto producers outsource. At Pio Tosini, the in-house deboning is not done automatically when the hams reach a certain age; rather, the deboning is done to order. The hams are ready to enjoy upon opening with no further trimming required.

And there’s more! More going above and beyond. More dedication to tradition and quality.

And there’s more! More going above and beyond. More dedication to tradition and quality.

It used to be that all prosciutto di Parma producers would totally stop production during the spring months because the hormonal changes in spring pigs impact the quality of the fat. During more recent years, pigs have been specifically bred to minimize the changes in the fat which allowed for year-round production. However, at Pio Tosini, they still notice a difference.

Adhering to the traditional method means a lower yield but a higher and more consistent quality.

So, indeed keeping simple might be the hardest work out there. It requires zero shortcuts, a commitment to tradition and trust and patience in letting time and nature do what it does best.

Written by Leska Tomash